The Exploitation of Rare Earth Materials

Published: 18th March 2020

Until 40 years ago, rare metals were unknown elements for most people, with exception to those who studied the Periodic Table of Elements in it's entirety. Today, these metals are essential for the connected society and they are used in robots, cars, artificial intelligence, nano-electronics, and more.

”All the most strategic sectors of the economies, all the new technologies, which are focused on our way of consuming energy, even our large collective decisions, will reveal themselves totally dependent on rare metals” says French journalist Guillaume Pitron in his latest investigation. From the 1970’s, the magnetic, catalytic and optical properties of rare earth materials have been studied and new applications have been founded. These properties make rare elements essential to any developed society.

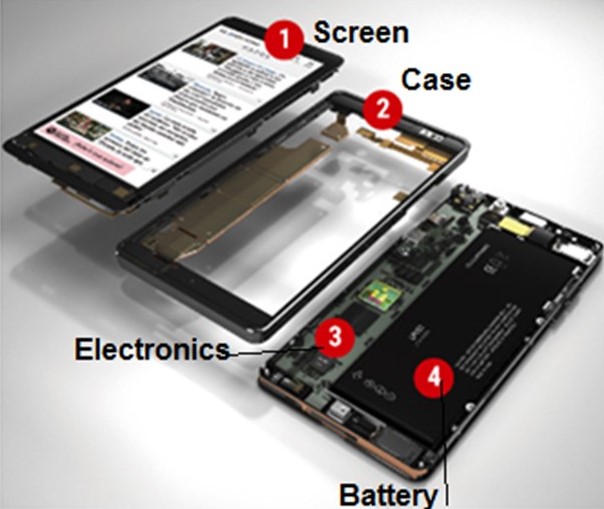

A smartphone can include up to ten different rare elements. The picture below shows the different elements found in a smartphone. Yttrium, Lanthanum, Terbium, Praseodymium, Europium, Dysprosium and Gadolinium are used in small quantities to produce the colours of smartphones’ screens. In addition, rare element compounds can also be used to reduce UV light penetration into the phone.

The screen can contain Indium (In), Oxygen (O), Tin (Sn), Aluminum (Al), Silicon (Si), Potassium (K), Yttrium (Y), Lanthanum (La), Terbium (Tb), Praseodymium (Pr), Europium (Eu), Dysprosium (Dy) and Gadolinium (Gd).

Casing: Carbon (C), Magnesium (Mg), Bromine (Br), Nickel (Ni)

Battery: Lithium (Li), Cobalt (Co), Oxygen (O), Carbon (C), Aluminum (Al)

The electronics contain: Cooper (Cu), Silver (Ag), Gold (Au), Tantalum (Ta), Nickel (Ni), Terbium (Tb), Praseodymium (Pr), Dysprosium (Dy), Gadolinium (Gd), Neodymium (Nd), Silicon (Si), Oxygen (O), Antimony (Sb), Arsenic (As), Phosphorous (P), Gallium (Ga), Tin (Sn), Lead (Pb)

The exploitation of rare earth metals is known to be associated with controversial approaches as consequence of their natural occurrence, processing and environmental impacts.

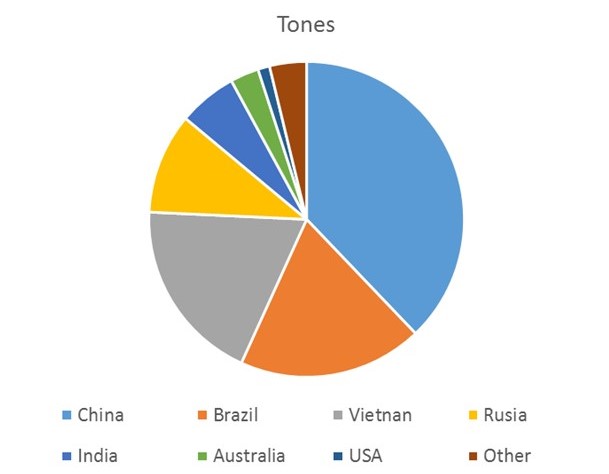

Firstly, China currently produces more than 90 percent of the world’s supply of rare earth materials and in the event of a conflict, China could control prices for the other countries or even shut down production of rare elements altogether. The image below shows the world reserve for the exploitation of rare elemental material over the world.

Secondly, the concentration and refining of rare earth ores is a challenging process. Rare earths don’t clump together in single-element lumps. Instead, they bond freely with one another in minerals and clays. Thus, to produce rare earths from the ore, the extracted material has to be dissolved in solutions of acids, over and over again, then filtered, and dissolved several times. Moreover, for each new mining site, the chemical processes have to be recalculated in order to target the specific impurities in the soil. The processing produces a great number of nasty chemical byproducts and in some cases even radioactive waste. It is required to refine 16 tonnes of natural rock to produce one kilogram of Cerium, 150 tonnes per kg of Gadolinium and 250 tonnes of rock per kg of Lutetium.

Another two aspects which are intimately associated with rare earth production, are the high safety and environmental risks. As a consequence of poor and dangerous mining conditions, there is a large amount of extracted rocks and by-products (e.g. large quantities of acidic solutions). The whole process of extraction, separation and concentration of rare elements is very expensive, dangerous and can be harmful. Scientists have highlighted the importance of reducing the exploitation of rare minerals and a lack of recycling schemes to recover them from current uses. It is estimated that about 10 million smartphones are replaced every month in the EU alone.

The Analytical Services department at Sheffield Assay Office have the testing facilities available to determine the rare element contents from low parts per billions, to percentages for a wide range of applications. If you'd like to find out more about the variety of tests and services available, please get in touch.

The Sheffield Assay Office was established in 1773, under an Act of Parliament and today the company assays and hallmarks the precious metals - silver, gold, platinum and palladium. Sheffield Assay Office is one of only four UK assay offices who all work to uphold the Hallmarking Act of 1973 and continue to ensure consumer protection for customers purchasing precious metals.

To find out more about the whole range of services offered by Sheffield Assay Office, such as our hallmarking and analytical services, please email us at info@assayoffice.co.uk or complete the contact form on our website at http://www.assayoffice.co.uk/contact-us ,

Sign up here to all the latest news from Sheffield Assay Office direct to your inbox