Does your jewellery REACH the standard?

Published: 12th December 2019

The UK Assay Offices processed over 9 million articles of precious metal jewellery every year, testing the content of gold, silver, platinum and palladium and applying the appropriate hallmarks.

But did you know that there are other legal requirements which jewellery has to meet? Nickel, lead and cadmium are three metals which are also regulated, but many retailers are unaware of the rules, which also apply to costume jewellery made from non-precious metals.

During a wide-ranging European enforcement project involving 29 countries, inspectors checked 5,625 products and found that 12.1% of jewellery tested contained cadmium above the restricted concentration limit. Almost 7% contained prohibited levels of lead, and nearly 8% had nickel above restricted limits.

What is REACH?

REACH stands for Registration, Evaluation, Authorisation and Restriction of Chemicals, and is the EU Regulation (EC) No 1907/2006.

It is the system for controlling chemicals in the EU and became law in the UK on 1st June 2007, replacing a number of directives and regulations with a single system. These legal requirements will remain in UK law immediately following Brexit.

REACH aims to provide a high level of protection of human health and the environment from the use of chemicals, by making the people who place chemicals on the market (manufacturers and importers) responsible for understanding and managing the risks associated with their use.

A substance on its own, in a mixture or an article, for which Annex XVII contains a restriction shall not be manufactured, placed on the market or used unless it complies with the conditions of that restriction.

For items of jewellery, the specific annexes apply to anyone who supplies products which contain lead or cadmium. Also affected are articles intended to come into direct and prolonged contact with the skin and contain nickel. This includes articles such as rings, earrings, bracelets, body piercing items, necklets, chains and watch straps.

Nickel

Nickel is an abundant metallic element, and is often used to create a white colour in gold jewellery. Its low cost also lends itself to being widely used in the costume jewellery industry, and is often found in plating layers.

Prolonged contact with these products may lead to nickel sensitisation, which is the most common cause of nickel contact dermatitis.

Nickel has to be present on the skin in the form of nickel ions in a solution, such as sweat. So rather than restricting the total content of nickel within the alloy, the REACH legislation sets limits for the migration of nickel from the article; 0.5 mg/cm2/week for articles intended to come into direct and prolonged contact with the skin (non-compliant below 0.88 mg/cm2/week) and 0.2 mg/cm2/week for all post piercing assemblies (non-compliant below 0.35 mg/cm2/week).

There is no correlation between how much nickel is present in the alloy and how much of it will migrate (some stainless steel watches contain up to 28% nickel but do not release enough to cause an issue). Also, the manufacturing process may alter the physical properties of the metal, so simply testing the raw material may not indicate that the finished product will pass the test.

.jpg)

Lead

Lead is a heavy metal that has often been used in jewellery to make the item heavier, brighten colours in paint, and to soften plastics. However, lead is also a toxic metal which accumulates in the body and even low doses can eventually lead to poisoning.

Products may not be placed on the market if any individual component of the article of jewellery contains lead equal to or greater than 0.05%. This applies to jewellery and imitation jewellery articles and hair accessories including bracelets, necklets, rings, piercing jewellery, wrist watches and bangles, brooches and cufflinks.

Certain exemptions apply, such as for crystal glass and non-synthetic precious and semi-precious stones.

Cadmium

Cadmium is also a harmful chemical added to alloys in small quantities to improve the functional attributes of metals or as a lead substitute. It can be present in jewellery as part of the solder, coatings or the plating process, and can also be present in the pigment of non-metallic materials.

The REACH regulation restricts the levels of cadmium in jewellery and hair accessories to 0.01%. This applies to metal components and plastic materials. The regulation also states that cadmium levels in paints and enamels need to be 0.1% or less.

What do I need to do?

If you are not the manufacturer or importer, firstly you should check with your supplier that the products comply with the regulations. Ask for test certificates as evidence. If you are a manufacturer or importer, you should have your products tested using a reputable laboratory. Failure to comply with trading standard laws may result in a fine or imprisonment. You must carry out your due diligence, as doing nothing is not an acceptable option.

Testing

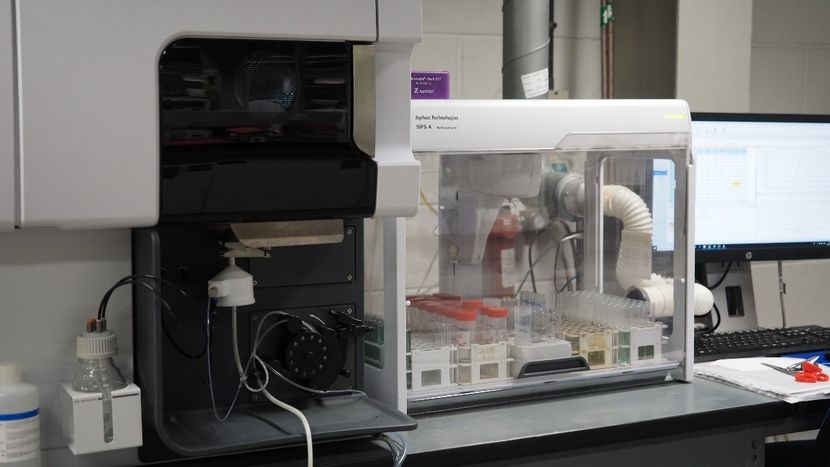

In order to support the nickel release legislation, Sheffield Assay Office can test items to the reference test methods BS EN 1811:2011 + A1:2015 and BS EN 12472:2005 + A1:2009. This involves simulating 2 years wear and placing the item in an artificial sweat solution.

We test items for lead and cadmium using an in-house developed method which is based on the CPSC-CH-E1001-08.3 and CPSC-CH-E1003-09.1 methods for lead in children’s metal products & paint. This involves dissolving the individual components in acid.

The resulting solutions are then analysed using instruments which can detect metals in solution at a very low level. Our highly trained analysts use ICP-OES and ICP-MS for this, and we have many years of experience as a UKAS accredited laboratory doing so.

There are a number of factsheets on the download page of our website. Please contact our Analytical Services department for further information on how we can help you remain compliant.

For additional information, you can contact the UK Reach Competent Authority via the HSE website https://www.hse.gov.uk/reach/contact.htm

The Sheffield Assay Office was established in 1773, under an Act of Parliament and today the company assays and hallmarks the precious metals - silver, gold, platinum and palladium. Sheffield Assay Office is one of only four UK assay offices who all work to uphold the Hallmarking Act of 1973 and continue to ensure consumer protection for customers purchasing precious metals.

To find out more about the whole range of services offered by Sheffield Assay Office, such as our hallmarking and analytical services, please email us at info@assayoffice.co.uk or complete the contact form on our website at http://www.assayoffice.co.uk/contact-us ,

Sign up here to all the latest news from Sheffield Assay Office direct to your inbox